What are industrial weighing scales?

An industrial scale is a weighing machine typically used in trade and commerce catering to large qualities of products in their operations. These scales measure a wide range of objects depending on the type of application, environment and product.

Essentially, industrial weighing scales vary in size, shape and design to ensure operational reliability and efficiency. They are best used for manufacturing, distribution, construction and logistics but can also be a good option for energy facilities and other large-scale businesses.

If you are looking for an industrial weighing system that suits your needs, it helps to know their types before purchasing one.

Types of Industrial Weighing Scale

1. Bench Scales

One of the most portable weighing scales used by manufacturers is the bench scale. If you are measuring small quantities of objects, materials or chemicals, this type of scale is the perfect option for you. Manufacturing companies for medicine, jewellery and food are the primary users of these weighing systems.

Typically, a bench scale has a flat surface called the platform whose size varies according to your needs. It also has a set of function keys and an LCD where you can read the measurements.

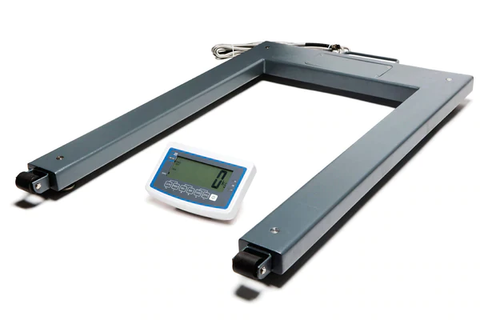

2. Platform Scales

Just like a bench scale, this type of scale includes a platform but on a bigger scale, hence, great for bigger quantities of measurement. Due to their wide bases, they offer more stability since items can be stacked on top of them.

In most cases, platform scales use load cells placed strategically underneath the platform. This offers the opportunity to customise your weighing scale to allow weight precision and large load capacity.

Some platform scales are designed with ball casters or wheels for portability, especially if you have some space constraints. There are engineered to withstand rough weighing activities day in and day out.

3. Floor Scales

The purpose of floor scales is to weigh raw materials, finished goods, or other products as they move throughout a production facility. The good thing about the latest models of these types of scales is the integration of computing software in their systems.

Most floor scales do not just provide measurement readouts but also keep track of the inventory. The data can also be stored and retrieved from a database saved on your computer, tablet or smartphone.

These scales are similar to platform scales but of a larger size. They are best used in manufacturing and distributing companies for food and beverages. However, floor scales can also be used in agriculture and farming, as well as logistics and aviation.

4. Truck Scales

A truck scale is an essential piece of equipment that truck drivers must place their trucks on, so they can be weighed accurately. These scales usually feature a constructed platform that offers a flat metal surface for trucks to drive onto, allowing for precise weight readings to calculate freight costs too.

Without truck scales, truckers would essentially be driving in the dark, not knowing their vehicle's exact weight. They are engineered with sophisticated pieces of components and computing systems that are paramount in keeping truckers safe and the roads regulated for everyone’s sake.

Whether you're hauling for business or personal use, truck scales give truckers and truck companies an accurate measure of their carrying capacity. Some companies install their truck scales at weigh stations located along major trucking routes. This helps drivers use them conveniently and efficiently when they need to weigh their trucks.

5. Crane Scales

A type of hanging scale that’s capable of carrying larger loads is the crane scale. This type of scale is primarily used in manufacturing large machinery, equipment and vehicle. They can also be used in logistics, aviation and construction.

Comparatively, while most types of weighing devices used force, crane scales depend on tension while the item is being suspended in the air. The best part of using cran scales is their ability to measure odd-shaped objects.

What should you look for when buying an industrial scale?

Choosing the right weighing system for your business is a big decision to make. After all, it will become a part of your investment. For this reason, it is important to consider stability and accuracy. You may also look into the machine’s resolution for added reliability.

● Accuracy

Not all weighing scales are created equal, so it helps to choose and buy from a supplier where precision matters. Make sure that the industrial weighing scale you are purchasing can provide the desired accuracy you need.

● Capacity

When looking into scales, one of the most important things that you should take into account is the weight of the heaviest and largest item you need to measure. It helps to choose a scale that can accommodate and endure repetitive weighing of these kinds of loads.

● Resolution

A scale's resolution is its capability to measure the smallest weight. Your results will yield more accuracy if your scale has a higher resolution. And a favourable resolution leads to more coherent and definitive results.

Generally, having a quality industrial weighing scale is the best investment you can provide your business. So it helps to find a reputable source to safeguard your interest.

Contact Meltrons Australia for the weighing system that suits your industrial needs!